After testing the mufflers for the first time there was an extreme popping upon

deceleration. So, until I can find a cure I suggest not tearing into your mufflers.

It looks as if I need to richen up my Power Commander. If you don't have any PC

or chip to put in, I suggest not performing this mod. I don't want you to do any

irreversible mods and have it sound like crap. Thanks.

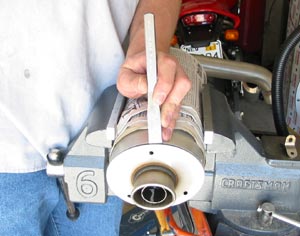

Sawzall, Vice or Clamp

choice) or to a table using a c-clamp or something similar. Then,

take your drill and drill out the three rivets on the end and the two

rivets holding the bracket on the side.

safety goggles for all this impact work!

tap around the perimeter of the end cap to separate it from the

aluminum shell. You'll see that it'll come free with some effort.

out. It'll just drop out once you pound it out enough.

end on. Grip the whole muffler like shown, and raise it up like a

caveman trying to bludgeon dinner.....

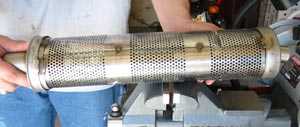

bashings, the shell should separate from the body of the muffler,

and you can drag it out. The pic I took of what it likes like after

this didn't come out, but scroll down to the reassembly to see the

packing you will encounter.

out, and trace around it on the end of the body to get an idea of the

size of hole we're cutting out.

worked as good as this method. Plus, it's cheap. So, we first take

our center punch and tap all along the line we drew so that it has a

bunch of punch marks in it as a guide.

started. That's right, chisel!

metal chisel and safety goggles. I tired a holesaw, a grinder, I tried

drilling all the way around, and I tried the reciprocating saw, but

they all were less than ideal. This metal is TOUGH, and the chisel

surprisingly ripped right through it more accurately than I thought.

the chisel a sort of track to follow. The total process took only

about 5-10 minutes each.

into your hands. We can ditch those now.

makes no difference to me since: a) it'll be covered by the

end cap, and b) it doesn't affect the operation or integrity

of the muffler at all. So, you can grind yours down but in

my opinion it's a waste of a bit.

semi-original condition from when we hacked it open.

because I like my neighbors. Just wrap it like you're

wrapping electrical tape- nice and tight and even. But, be

careful, this stuff is murder. Its little synthetic fibers

embed in your clothing and skin, and itch and scratch like

hell!

tight enough it should go on very easily.

body and tap it hard on something soft, like a stack of

newspapers. I used a tree stump, but this picture is just for

illustrative purposes. You don't want to bash up the aluminum,

so don't whack it too hard.

rubber dead blow hammer. Make sure you get the cap right side

up so it lines up with the holes in the side and top correctly.

have a high quality riveter yet, but it's a simple step that I don't

need to explain. The difference is clear- I can't wait to hear how

it sounds!

herein are those of myself and do not reflect those of Ducati or its affiliates. The "DUCATI" logo and "Circle D" are registered trademarks of Ducati Motor

Holding, S.p.A., all other content on this website is copyright 2006, Monster Man Productions.